Copper Powder

Copper powder is produced through a water atomization process of molten alloy, primarily copper, and other chemical elements that provide different properties required by our clients. Depending on the water pressure and the flow rate of the molten alloy, the copper powder varies in particle size upon exit. It is classified in mesh units. The larger the mesh size, i.e., the higher the mesh value, the smaller the particle size and the greater the surface coverage. Its main applications are in the milling industry, diamond tools, transportation, particularly for brake components, and chemistry.

Process

Water atomized copper powder + sieving

Composition

Cu (98.5% to 99.5%) ; Sn (0.2% to 0.3%) ; Mg (0.02% to 0.2%)

Apparent Density

2.00 g/cm³ to 4.50 g/cm³

Particle Shape

Irregular

Particle Size Distribution

400µm to 40µm

Color

Orange (ochre)

Process

Water atomized copper powder + crushed + sieving

Composition

Cu (97% to 99.5%) ; Sn (0.015% to 0.02%) ; Fe (0.02% to 0.1%)

Apparent Density

0.80 g/cm³ to 2.50 g/cm³

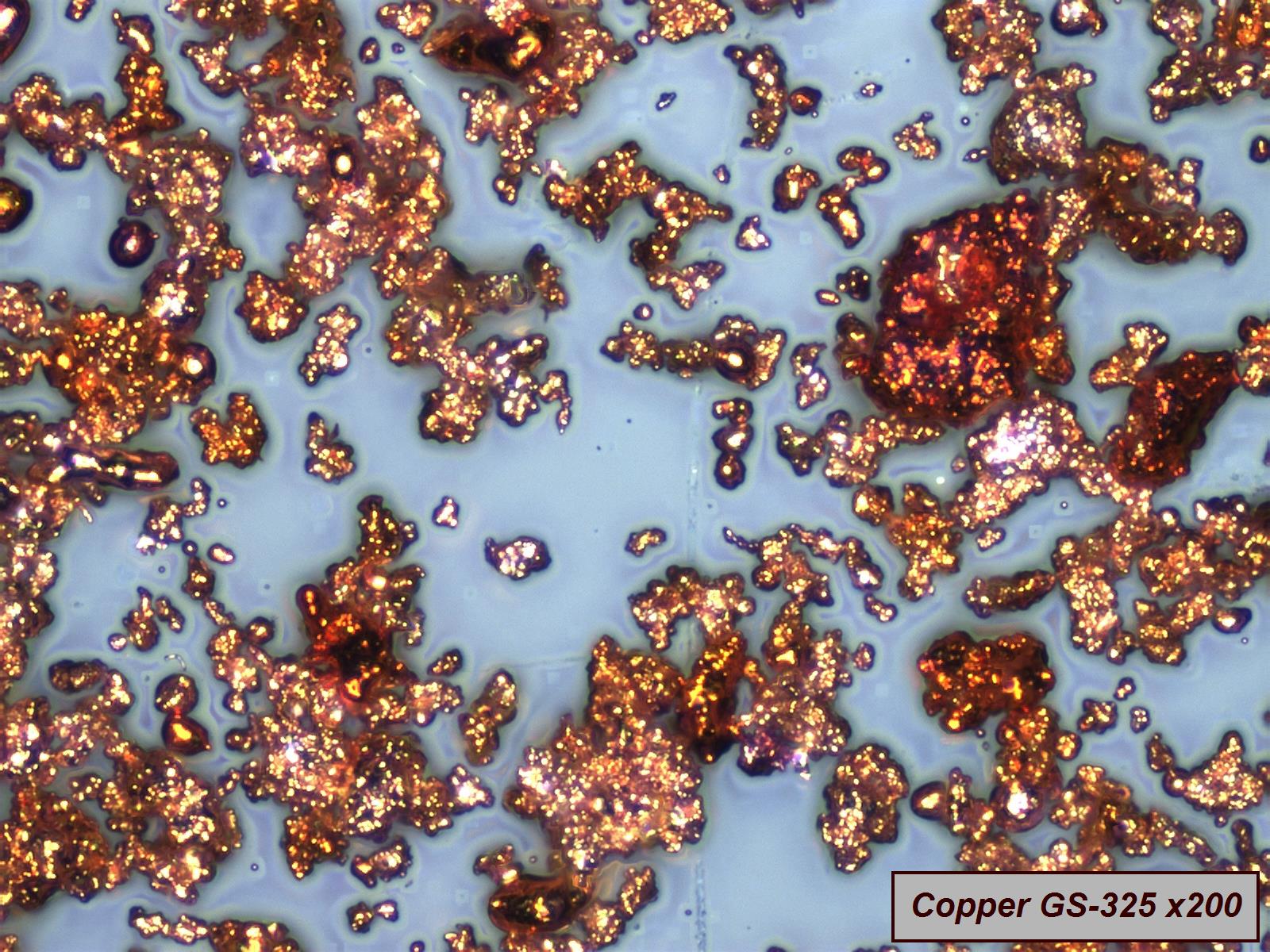

Particle Shape

Lamellar

Particle Size Distribution

160µm to 40µm

Color

Sparkling Copper