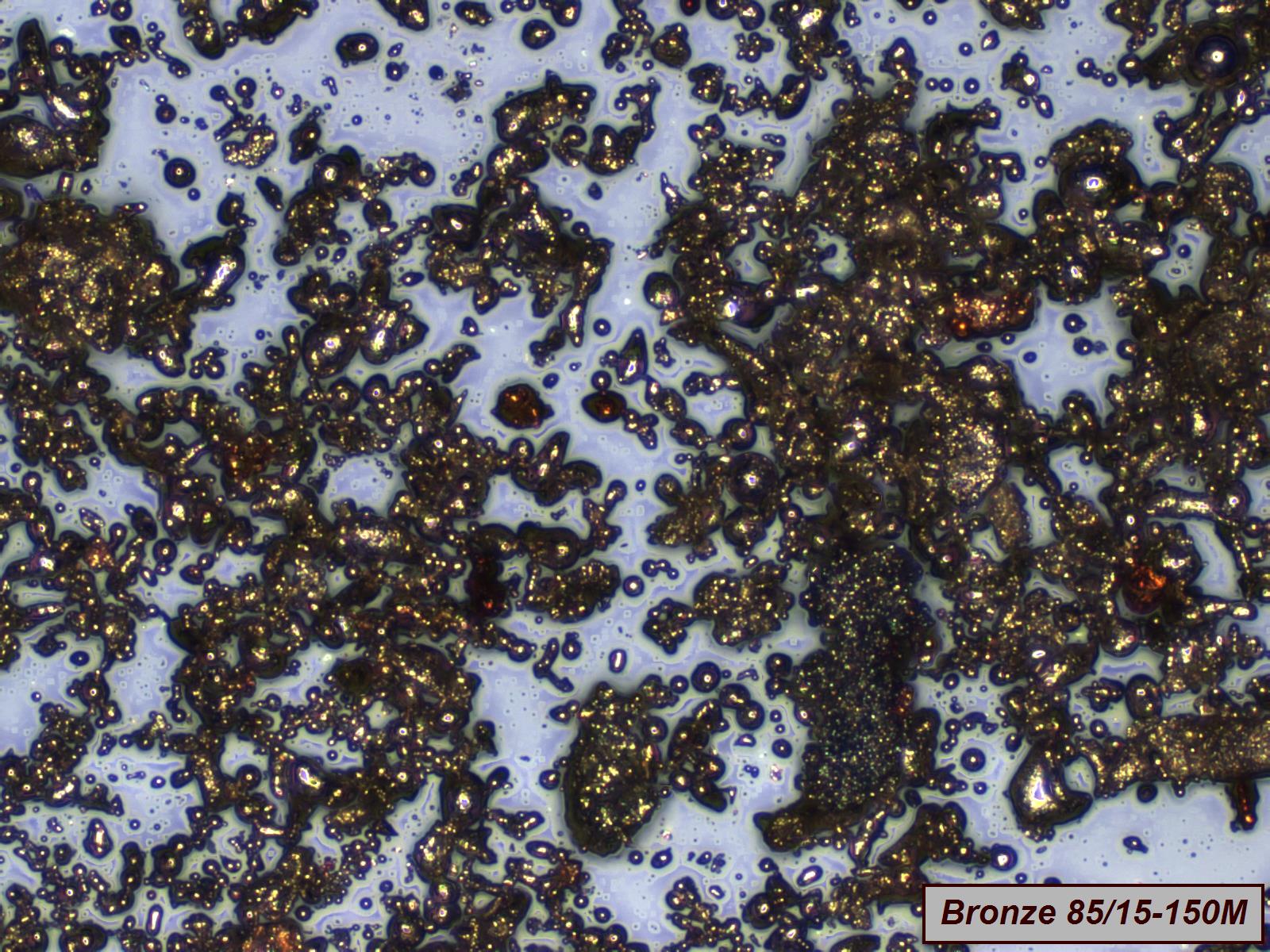

Bronze Powder

Bronze powder is obtained through a water atomization process of a molten alloy mainly composed of copper and tin. Depending on the water pressure and the flow rate of the molten alloy, the resulting bronze powder varies in particle size. It is divided into mesh units. The larger the mesh, meaning the higher the mesh value, the smaller the particle size and the higher the surface coverage. Its main applications are in the milling industry, diamond tools, and transportation, particularly for brake parts.